Secure the crucial procedures in the slaughterlLine by automated monitoring

Avoiding pigs to pass the sticking alive is of utmost concern in the slaughter line. By replacing manual monitoring with automated vision-based monitoring the procedure is secured to the maximum while reducing costs.

In the many steps in the slaughter process of high-capacity slaughterhouses automation helps secure efficiency and, not least, consistency in procedures. This is no less true for the monitoring of the sticking procedure. To avoid that live pigs are transferred to the next stage of the process it is absolutely crucial that every pig is stuck before further processing.

In most slaughter lines in Denmark and throughout the rest of the Nordics a vision-based monitoring system is installed to automatically and reliably examine each pig.

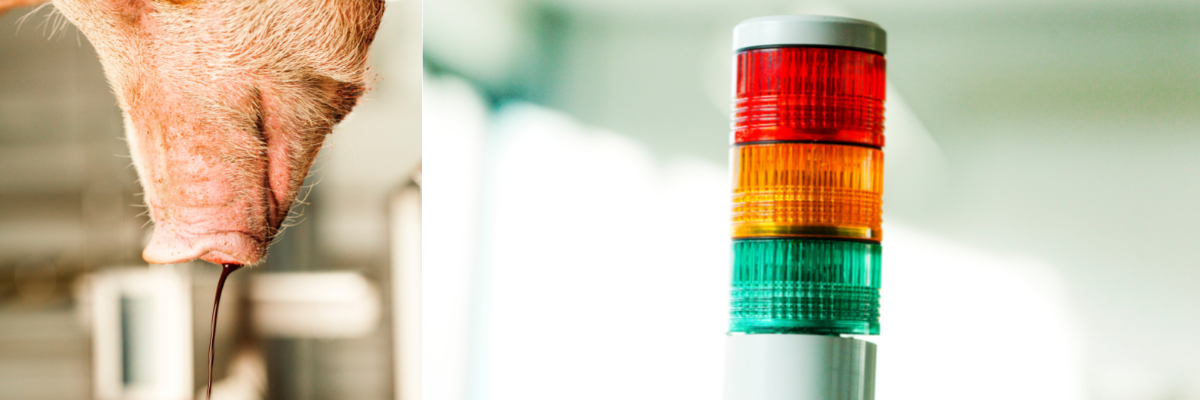

The innovative monitoring system, VisStick, provided by Danish Meat Research institute alerts the operator to secure proper sticking. If no blood dripping from the pig’s snout is registered, the system gives an alarm.

The capacity is greater than 1400 pigs per hour and it replaces manual inspection

VisStick is installed at the line with no or very few modifications to existing line. The capacity is greater than 1400 pigs per hour and it replaces manual inspection.

This innovative Danish technology is for improved slaughterhouse animal welfare, to give your company assurance that the risk of unstuck pigs continuing on the slaughter line is minimal. And by replacing the need for visual human control, it adds considerable cost reduction.