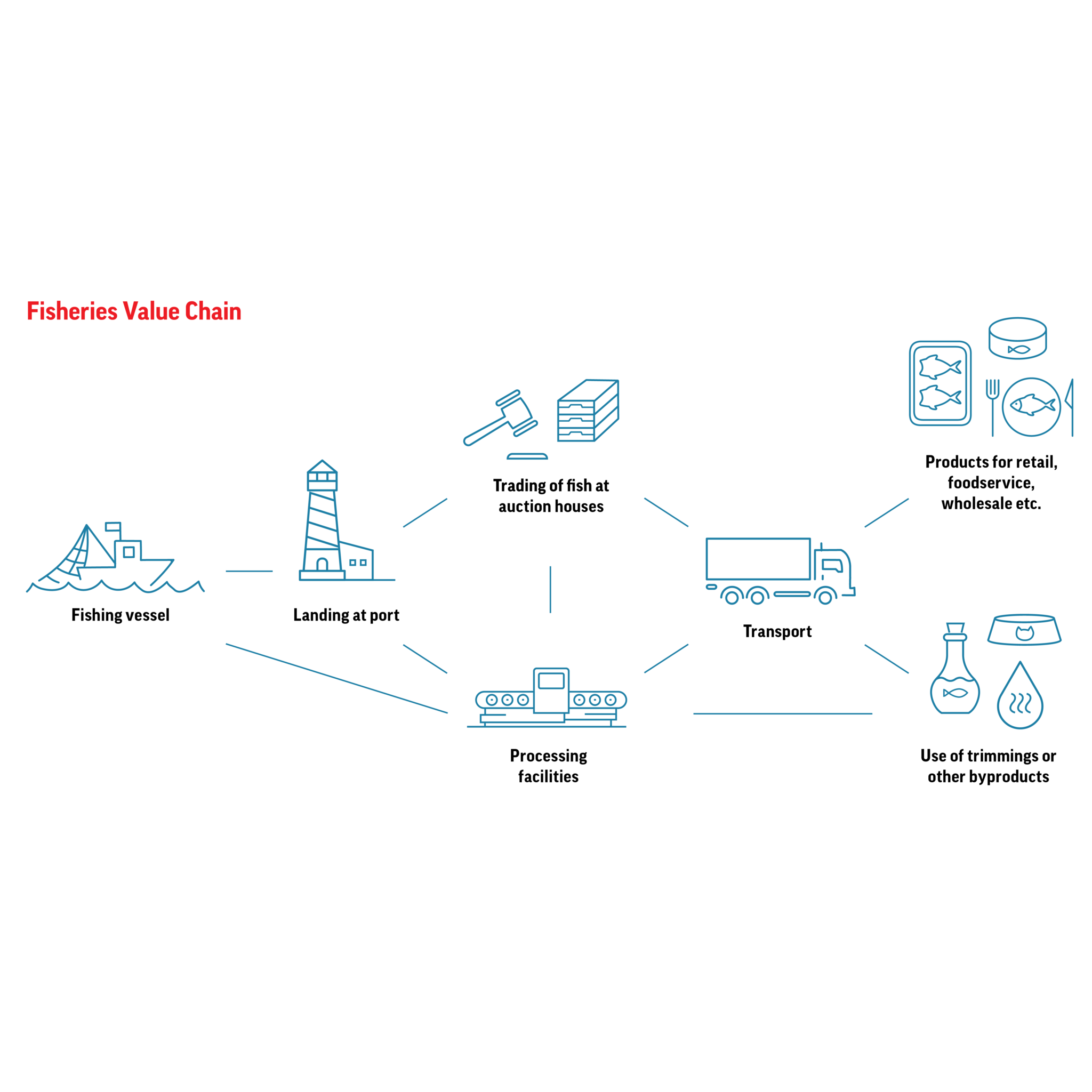

Fish trimmings and other side streams are no longer regarded as waste but as important raw materials for high-value ingredients for food, feed and health products for human consumption.

The Danish fishing industry has an ambition to create value from 100% of the seafood caught at sea or raised by aquaculture. Trimmings from fish fileting, bones, shells, skin and viscera – all have a value to explore and realise in ingredients for food, dietary supplements, pet food and feed.

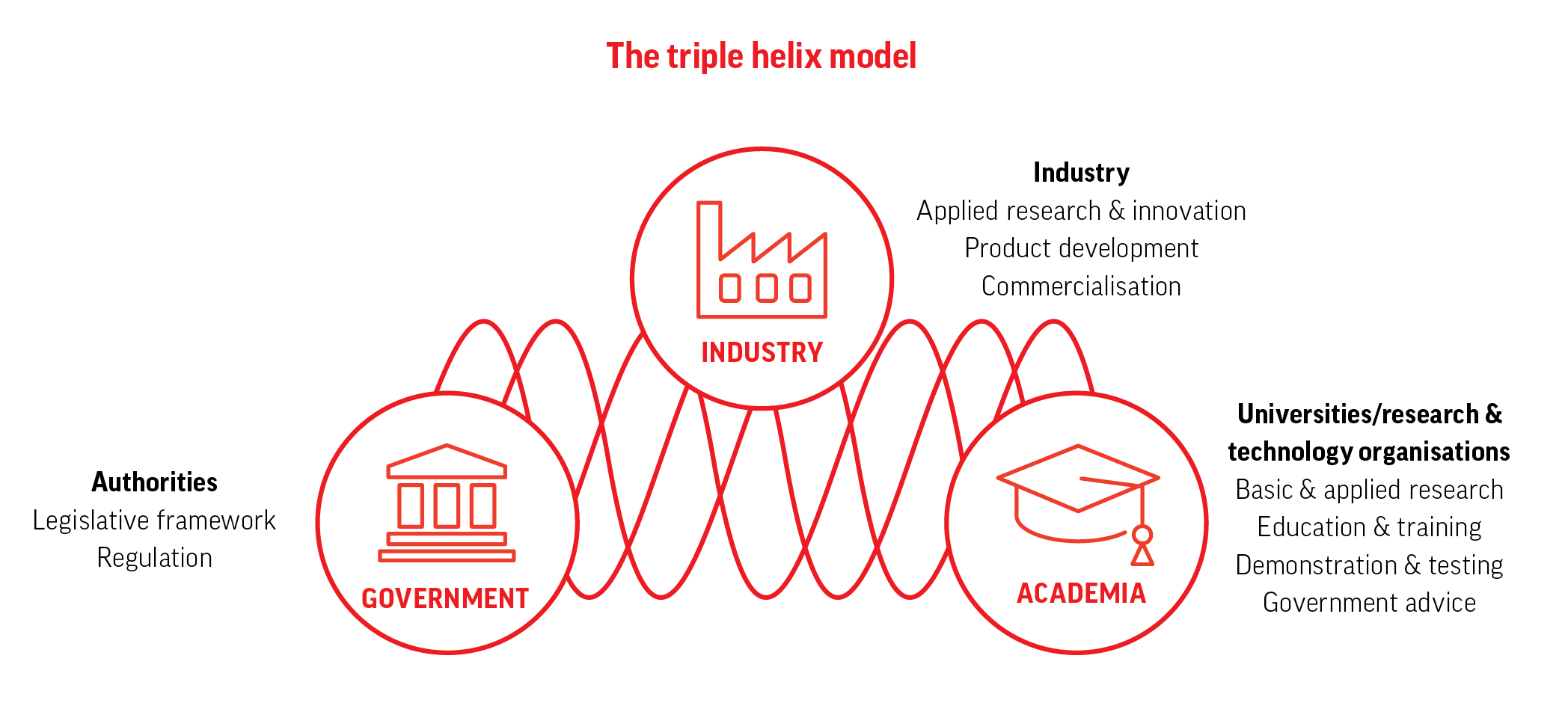

Public-private collaborations in Denmark are constantly searching for new ways to make most efficient use of every component. In the pharmaceutical sector, the potential of bioactive marine compounds is consequently just starting to be revealed. At the lower levels of the value chain, seafood sidestreams are utilised as feedstock for biofuel production.

Denmark is Europe’s no. 1 producer of fish-meal and fish oil, producing more than 190,000 tonnes and 52,000 tonnes, respectively, a year and exporting to more than 40 countries worldwide. Along with side-streams from fish production for the consumer market, the raw materials are primarily short-lived pelagic species, such as sprat, Norway pout, sand eel and herring.

The fishmeal industry can look to Danish enzyme technology for solutions that optimise protein extraction while saving on energy consumption. The enzymes further enable the production of protein hydrolysates, natural flavours and flavour enhancers for the food industry.

Once all other opportunities for value creation are exhausted, the remaining seafood side-streams serve as feedstock for biogas production and, after degassing, as a fertiliser. A recent initiative launched at one of the Denmark’s primary fishery ports aims to convert protein-containing fishery waste-water into biogas. The biogas will be used to generate electricity and heat for the local community – the final link in a zero-waste value chain.

Expand to read more