Pump manufacturer turns fish waste into value

A Danish manufacturer of lamella pumps uses tested technology to protect the environment and generate revenue by utilising waste from fish and shellfish processing.

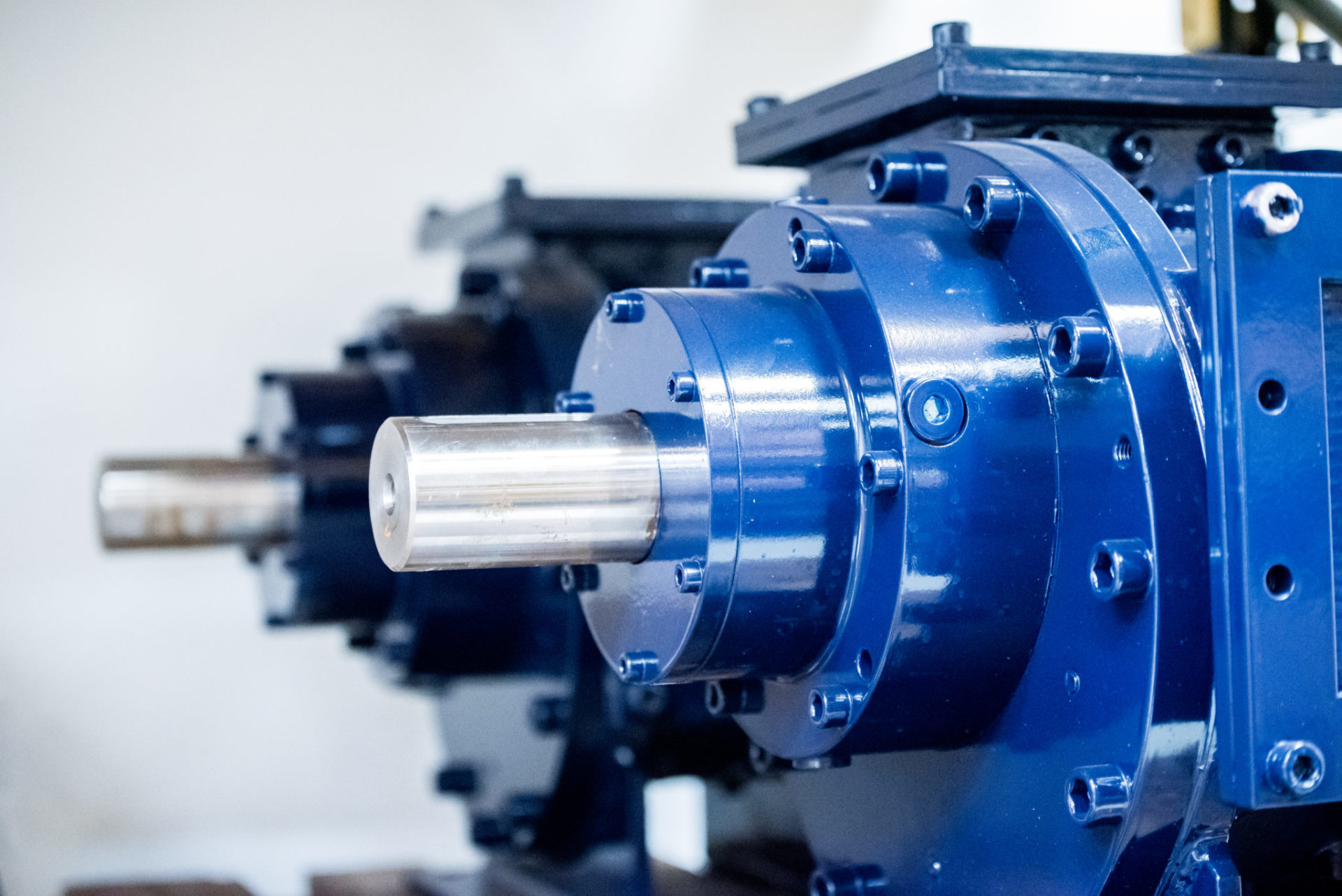

For years, JS Proputec has designed, produced and delivered pump solutions worldwide to handle waste and by-products. With their proven separation efficiency, the pumps are ideal for separating oil from the solids in seafood waste.

The pumps are part of the system that handles and transports seafood products during processing.

As raw materials are kept in a closed pipe system, the pumps improve hygiene while reducing odours. This capability and their compact design also mean they can replace screw conveyors, progressive cavity pumps, pressure tanks and conveyor belts.

Additional advantages include lower energy and maintenance costs, higher capacity and fully automatic operation – reducing labour costs and the risk of injuries.

From an environmental perspective, the use of fish waste ensures potential pollutant, such as nitrogen and phosphorus, are not released into the ocean, where they can have a negative impact on marine life

Instead, the resulting value creation contributes to food security by providing a sustainable source of protein for animal feed. It can also help sustain the industry and support local economies where fishing is a main source of income.

From an environmental perspective, the use of fish waste ensures potential pollutants, such as nitrogen and phosphorus, are not released into the ocean, where they can have a negative impact on marine life.