Freezing technology secures high-quality food products with lower energy consumption

Freezing food is one of the oldest and most used methods for food preservation. Choosing the right freezing technology can minimise production costs, increase food quality, and reduce energy consumption.

A Mid-West American poultry processing plant faced the challenge of using an old technology spiral freezer that required a high amount of maintenance and negatively affected food quality and food safety. The poultry processing plant was freezing marinated chicken fillets and bone-in chicken products and was experiencing reduced efficiency due to snow building up inside the freezer, reducing flow and throughput. Resulting in large amounts of bacteria growth, moisture product loss and reduced product yield.

The strength of all freezing technologies

The Danish company DSI Dantech is the only worldwide supplier of all freezing technologies, and the company cover the full range of IQF mechanical, cryogenic, and plate technology within industrial freezing, cooling, and heat treatment of food. They offer customized, sustainable, and profitable solutions for all industries including meat and poultry, further processing, fish & seafood to fruit, vegetables, and ready meals.

The new freezer technology has ensured consistency throughout the product, and resulted in 25% reduction in energy consumption

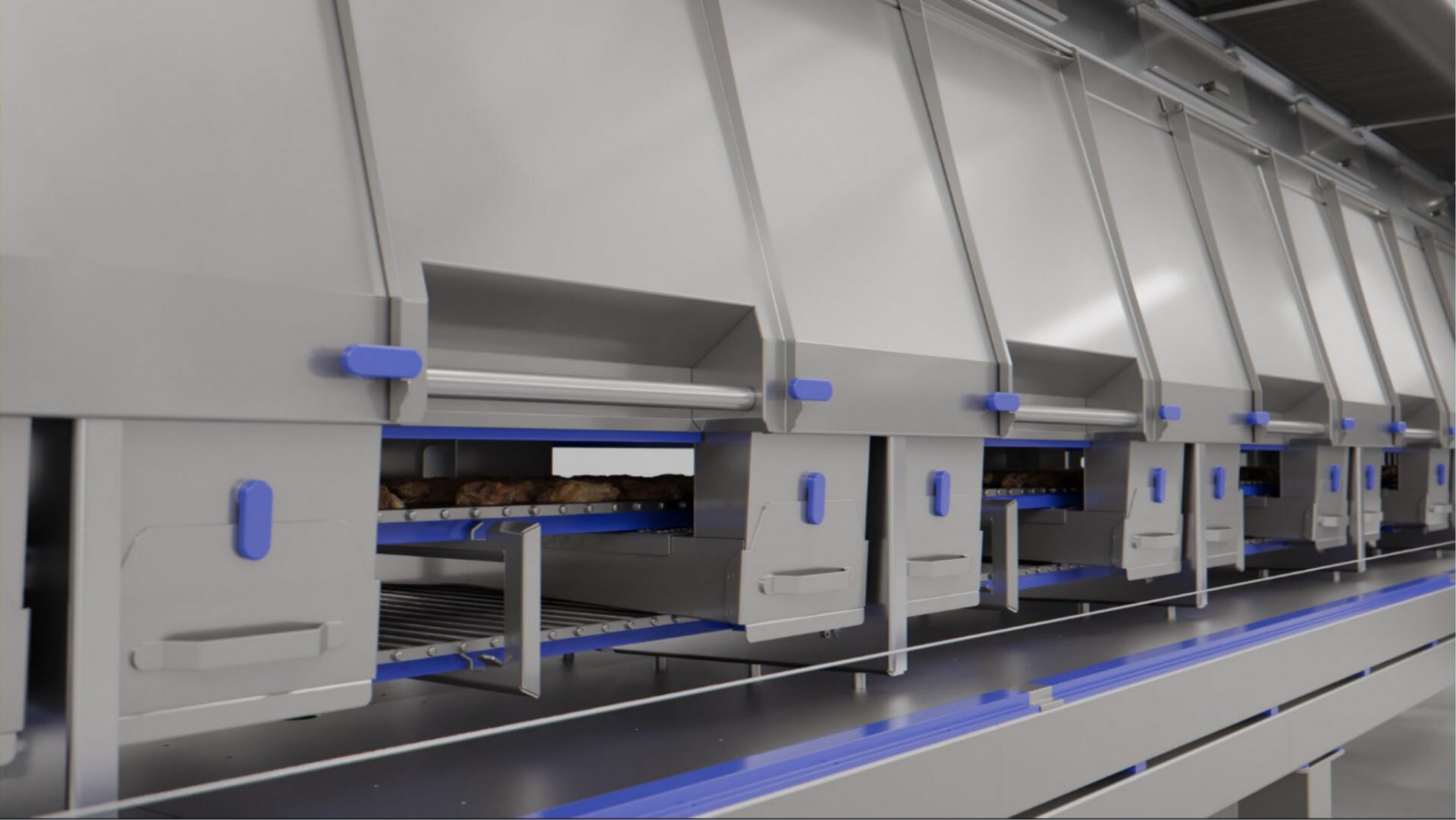

The US poultry processing plant chose DSI Dantech as their new partner, with focus on optimizing production costs, food safety and quality. The Ultraflow Impingement Freezer was installed which features a specially designed high-velocity airflow over the product and forms a streamline coating at more than 30 meter/sec. It is designed to quickly crust freeze the product in less than 2 minutes which helps retain moisture after injection and run along operating time without defrosting.

Extremely quick freezing ensures improved quality

Due to the implementation of the DSI Dantech freezing technology, the US poultry processing plant have reduced moisture loss and improved product yield. The quick freezing has increased product flow and throughput resulting in reduced production time and a total increase of 2,800 more pounds chicken produced and frozen every day.

In addition, food loss has been reduced as unevenly frozen products and bad appearance due to belt marks has been improved. Furthermore, the new freezer design has ensured consistency throughout the product, resulted in 25% reduction in energy consumption compared to other impingement freezers and improved the overall product quality.