Efficient food production needs a digital twin

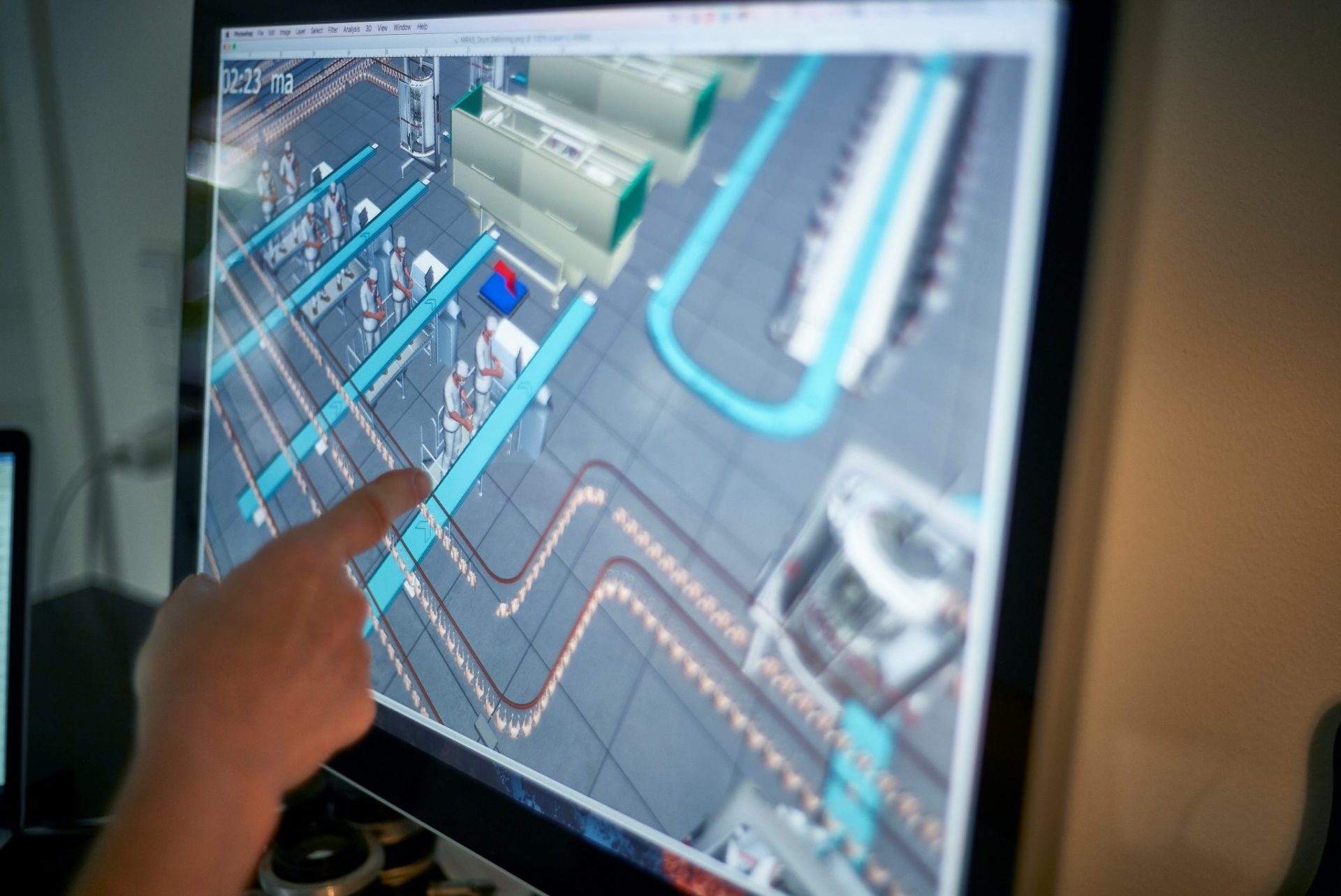

A real-time, virtual simulation tool developed by the Danish company, Niras, can help manufactures design and build complex production facilities. The tool lowers the costs and also the risks of a manufacturing investment due to more information about the facility prior to being build.

Demands on efficiency, traceability and food safety are growing fast in industrial scale food production, and that often calls for major investments in new or upgraded facilities. Danish consultant engineering company Niras has developed a digital tool to help manufacturers take the risk out of their investments.

The tool is a real-time, virtual simulation of the production process, line or plant – a digital twin, where all parameters can be finetuned for the best possible performance. Using this technology, manufacturers can then design and build complex production facilities in real life, often at lower cost.

By using a digital twin, manufacturers

can design and build complex

production facilities in real life at a

lower cost

Niras is building a strong track record in the field. For one dairy that needed a new microdosing system, the investment cost was cut by EUR 630,000 after a digital twin validated and optimised the design.

Continuous monitoring

Once a new processing line is in operation, the digital twin can continue to inform manufacturers about potential problems so timely adjustments can be made and preventive maintenance carried out. When new equipment is added or there is a change in the product mix, the digital twin can also predict the impact, including the risk of bottlenecks elsewhere on the line.

In one dairy assignment, a digital twin was used to validate and optimise the design of micro-dosing equipment for a new powder blending section. Bottlenecks were identified and removed, cutting the investment by EUR 630,000 in just three weeks of simulation work.

Niras has also successfully designed digital twins for the brewing, dairy, meat, poultry and fish industry.