Grain requires careful storage to preserve quality

Fast handling of grain in a dry environment makes the difference in grain storage. Danish JEMA offers a high-capacity grain pit and conveyor system.

On a Swedish farm just north of Trelleborg a need for more capacity and reliable dry handling of grain was met by Danish grain handling specialist, JEMA. The new DRY PIT installation in 2018 was among the most modern grain systems on the market and the facility is a success with dry, high delivery capacity and a design to optimise food hygiene.

Total capacity with the conveyor system is 105 tonnes per hour

Grain deliveries go into an 18 cubic metre suspended DRY PIT module. Total capacity with the conveyor system is 105 tonnes per hour. The high delivery capacity means everything is cleared up by the morning, even if harvesting went on late into the night. Manual handling in the morning is therefore a thing of the past.

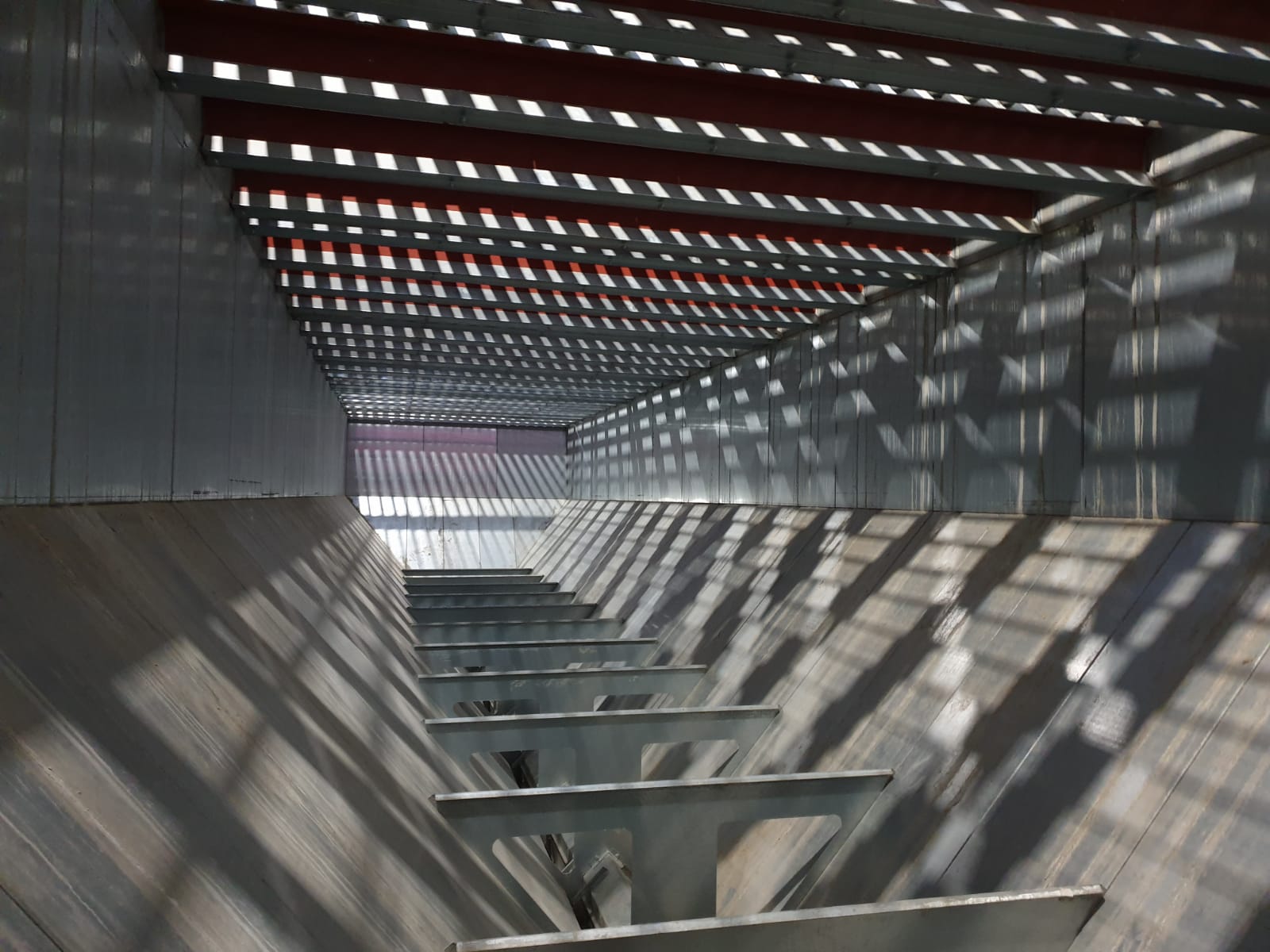

DRY PIT is suspended in a three-metre-deep concrete pit, and made of galvanised steel sheet. That means it is completely separate from rising groundwater around the sides and bottom. There are no flat surfaces on which old grain and dirt can accumulate. There is also full access to the pit, making it easy to service the pit auger.

This is yet another Danish high-standard solution available to the world market demanding clever and efficient contributions to sound and sustainable development in the global agriculture.